As solar and wind power increasingly replace nuclear energy and the permanently available fossil fuels, energy storage systems are becoming more and more important: green electricity is at the mercy of the whims of nature, and its production and demand are not always synchronised.

Mountain Tunnels Store Compressed Air and Heat

More electricity storage facilities are a must if our energy needs are to be covered from renewable sources. In future, compressed air energy storage systems can be used as batteries in the Alps, in the same way as pumped storage power stations.

At a glance

- Thanks to heat recovery, compressed air storage systems can store electricity with an efficiency of 65 to 75 percent.

- Compressed air storage is the only technology comparable to pumped storage in terms of efficiency and capacity.

- The world's first pilot plant is located in Switzerland and proves that the principle works.

A gentle alternative

Currently, pumped storage power stations are the only available storage option with large capacity and decent efficiency. However, such hydroelectric power plants are controversial as they are associated with a major impact on the landscape and the hydrological cycle. A technology that stores energy in a concealed setting would therefore come in handy, and compressed air storage technology in rock caverns is an interesting option. In this process, ambient air is pressed into a tightly sealed cavity in the rock, thus storing energy. The pressure in the cavern can later be used to drive a turbine and generate electricity.

Andreas Haselbacher of the Energy Science Center at ETH Zurich is convinced that compressed air storage has potential for large-scale power storage. He and his team are working on a thermal energy storage system, a key component in the process, that should make compressed air storage as efficient as pumped storage.

More power thanks to a thermal energy storage system

Heat is the inevitable by-product of air compression. In the compressed air storage systems currently in operation in Huntorf (D) and McIntosh (USA), this heat is dissipated and therefore lost. During subsequent power generation, the air must be reheated so that it is not too cold for the turbines. This procedure is not particularly economical and only restores somewhat less than half of the electricity required to fill the storage reservoir.

It would be much more efficient to store rather than waste this heat. In the present project, the scientists developed a storage tank that absorbs the heat generated during air compression and releases it back to the compressed air before its expansion in the turbine. Thanks to this heat recovery, the efficiency of power storage increases to between 65 and 75 percent.

An inseparable pair

One section of the thermal energy storage system consists of ordinary stones that heat up in the hot air stream. This phenomenon is called “sensible heat” storage. As the air flows through the pile of stones, it cools down from over 500 degrees to approximately 20 degrees Celsius, thus reducing stress on the rock within the chamber caused by high pressure.

A smaller storage tank is located upstream of the storage tank for sensible heat. During the charging process, this tank stores heat latently, i.e. invisibly, through fusion of a special metal alloy consisting of 68.5 percent aluminium, 26.5 percent copper and 5 percent silicon. When the chamber is discharged, the material solidifies and releases the stored fusion heat. Thanks to the balanced composition of the alloy, its temperature remains close to its 525-degree Celsius melting point during the solidification process. The latent heat storage system serves as a thermostat that prevents the released air from cooling down too quickly, protects the turbines and helps generate electricity with a constant output.

Pioneering work opens up new perspectives

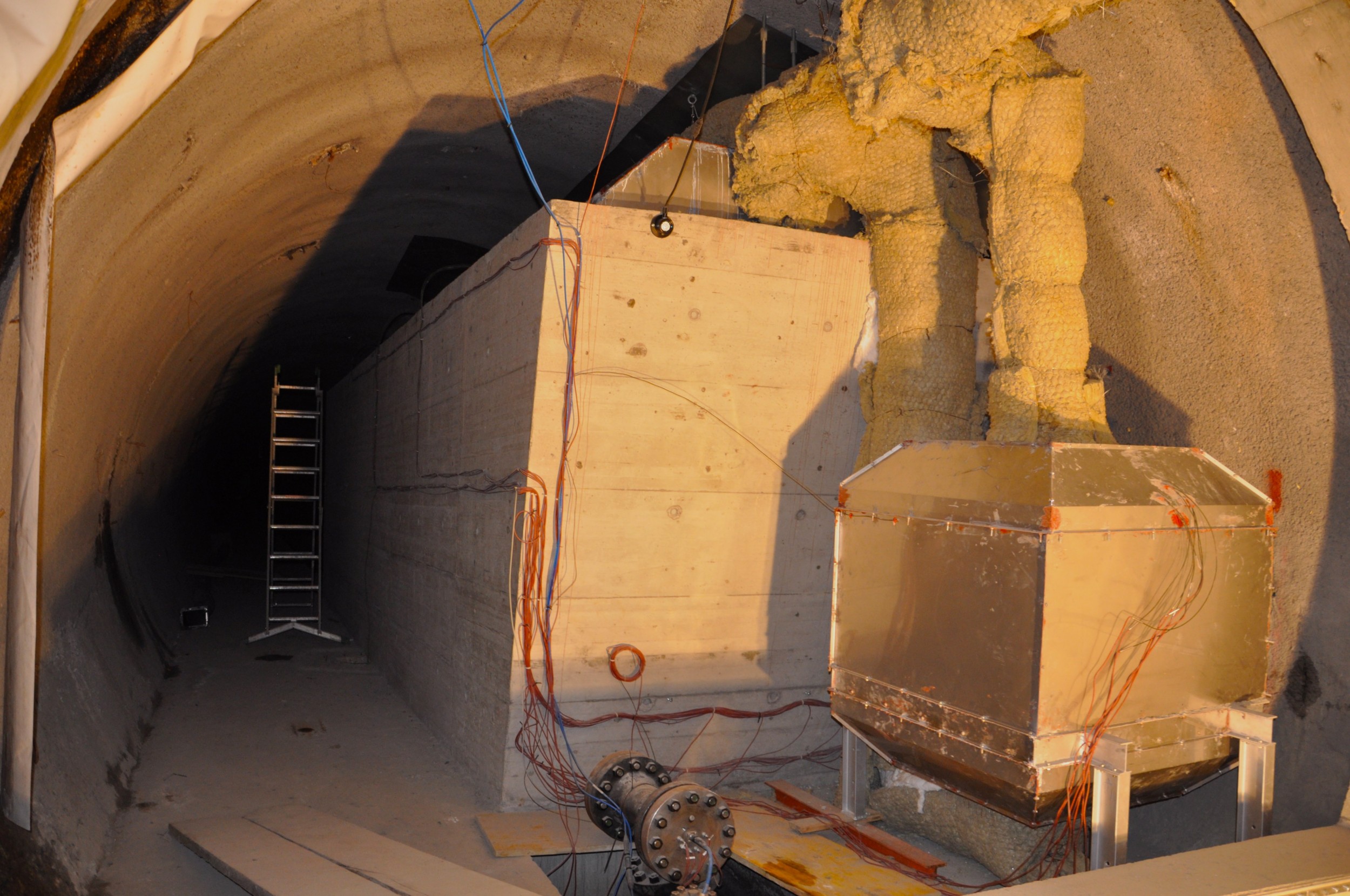

By way of the world's first pilot plant, which was built by the ALACAES company in a tunnel that was used during the construction of the Gotthard Base Tunnel, the researchers were able to demonstrate the functionality of this principle. By and large, the thermal energy storage system behaved according to the scientists’ expectations.

However, despite successful tests, there is still much room for improvement. For example, the latent heat storage system trials revealed leakage of the material contained in the tanks; a problem that should be easy to solve, says Haselbacher. A more interesting mission is to further optimise the composition of the storage material, so as to keep the temperature of the escaping compressed air as stable as possible. For this purpose, the researchers developed a new method that allows them to quickly identify interesting material mixtures.

With regard to the storage of sensible heat, the question is: which types of stone are best suited for storage? The investigators tested various stones by repeatedly heating and cooling them in the laboratory. Some stones do not withstand this ordeal undamaged. They lose specific heat capacity and therefore cool the hot compressed air less efficiently. However, this loss barely influences the performance of the system. Of much greater concern is the fact that due to stress some stones become porous and therefore disintegrate. Small stone particles can block the installation or even enter the turbine with the air flow and damage the turbine blades. However, stone types that withstand the heat treatment without becoming brittle and that appear suitable for long-term operation have already been identified, one of them being a serpentinite found in the Italian Alps.

Owing to the pilot plant and the complementary experiments, the researchers were able to learn a great deal about the technical difficulties of compressed air storage and heat storage. The technical feasibility having largely been clarified, the question of the economic efficiency of compressed air storage systems is increasingly present. Initial investigations have indicated that compressed air storage may be economical, which goes to show that this system, with its low environmental impact, deserves more attention as a storage option for large amounts of electricity.

Products of this project

Contact and Team

Dr. Andreas Haselbacher

Department of Mechanical and Process Engineering

ETH Zürich

Sonneggstrasse 28

SOI C 5

8092 Zürich

+41 44 632 69 05

haselbac@esc.ethz.ch

Andreas Haselbacher

Project direction

Viola Becattini

Peter Burgherr

Lukas Geissbühler

Christopher Mutel

Warren Schenler

Giw Zanganeh

Sub-projects

This project is part of the joint project “Electricity storage via adiabatic air compression”.

All information provided on these pages corresponds to the status of knowledge as of 12.06.2019.